Green logistics is defined as the holistic transformation of logistics strategies, structures, processes and systems in companies and company networks to create environmentally friendly and resource-efficient logistics processes. But what do sustainability, sustainable logistics and green logistics mean in practice?

Green Logistics: Green Logistics Strategies and Sustainability

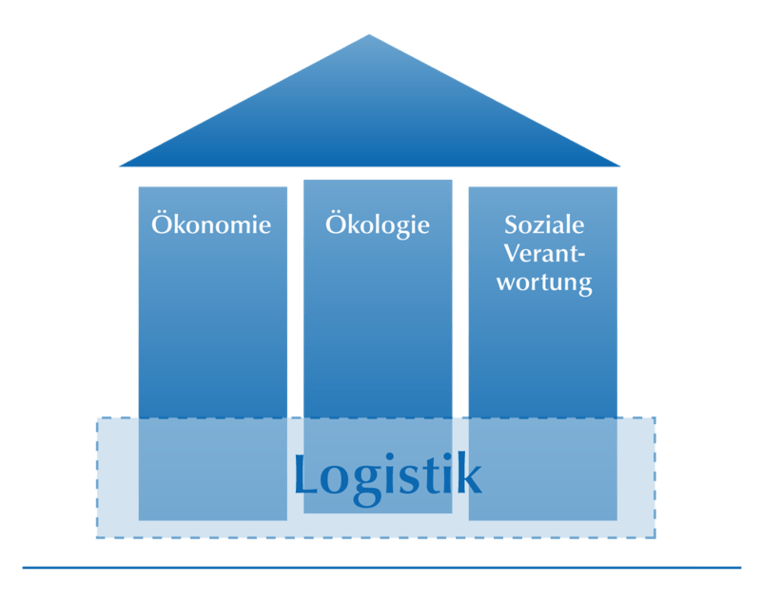

As soon as a company takes a closer look at green logistics, it quickly becomes clear that there is more to it than meeting emission limits and mandatory standards. The goals of green logistics include economic and ecological efficiency in equal measure and lead to the creation of sustainable corporate value. One thing becomes clear: sustainable management means that, in contrast to the purely ecologically sustainable target systems of green logistics, the classic logistics target system also includes environmental and resource costs.

Sustainable management – corporate green logistics

Definitions of sustainable management read like the tenets of a standard business textbook. However, green logistics has already become part of the practice of many companies. Every logistics company is affected by environmental issues to some extent, which is why environmental demands are placed on a logistics company from many sides. Sustainable management or sustainable logistics and logistics planning are therefore strategic necessities.

l

Prepare business decisions

- quickly find weak points

- external view of your processes

- cost-effective, quick results

Environmental sustainability in logistics

Environmental sustainability in logistics means taking a holistic and long-term view of the supply chain as part of all planning activities. Sustainable logistics includes all factors and elements of the logistics chain.

ORGAPLAN Logistik GmbH can play an active role as a logistics consultant in the following areas of Green Logistics to improve sustainable logistics in the company.

Traffic optimization

Route planning, tour planning

Optimization of vehicle structure (-mix)

Vehicle standards according to environmental standards

Traffic Shift

Cooperation proposals with partners

Increased efficiency in operation

Vehicle standards according to environmental standards

Consideration of sustainability aspects in warehouse planning and planning of logistics locations

Material flow simulation and optimization

Sustainable Economy – Economic Sustainability

Economic and social sustainability is no longer just a question of image and publicity. Green logistics goes further, because the entire logistics chain of a logistics company is now affected by various factors that increase the pressure on the company’s environmental awareness to make greater efforts towards environmental sustainability.

- Governments are stepping in with a growing number of international green logistics regulations.

- Customers and consumers are increasingly demanding a sustainable economy in the form of environmentally friendly products and logistics services.

- Our own employees want to work in an environmentally and socially responsible green logistics environment.

- Society, for example through non-governmental organisations, is increasingly approaching a logistics company with demands for social sustainability, and financiers such as banks or shareholders are increasing the pressure on logistics companies, up to and including stock market segments such as the Dow Jones Sustainability Index. This index attempts to evaluate companies according to ecological criteria and sustainable management.

- Logistics companies themselves are developing their own motivation to take a serious look at green logistics and to initiate green logistics measures.

Green logistics in the company – measures for sustainability

There are many starting points for implementing green logistics in your own company.

Green logistics and measures: The catalogue of Green Logistics measures to protect the environment and resources is structured at different levels and according to different criteria such as deadlines, scope, scale and use of capital and resources:

- Customer, market and product

- Business structures and strategic planning

- Operations, control and measurement, material flow

- Technology and resources

- Employees, suppliers and service providers

These levels therefore form a hierarchy and influence each other in ascending order. In other words, green logistics decisions at one level define the scope for further decisions at subsequent levels. So if you define a strategic decision at higher levels, the degrees of freedom at the subsequent lower levels are reduced.

Logistics and sustainability in action

A typical practical example of green logistics and action at different decision-making levels is a company’s decision to centralise its distribution warehousing.

First of all, the structural decision for a central warehouse represents a fixed point at the process level. From this central warehouse, a sub-range of products is distributed to the entire delivery area, which has a significant impact on the total number of kilometres travelled within the logistics network and on fuel consumption.

Of course, total fuel costs can be reduced by Green Logistics optimisation measures at subsequent levels. For example, you can minimise the total distance by using route planning software or fleet control systems. Or you can use site simulations to determine the ideal geographical location of logistics sites in the network. However, the more important decision has already been made at the strategic level of the central warehouse delivery concept.

The following therefore applies to green logistics: First, the strategy must be geared to sustainability. This is because measures to protect the environment and resources at the strategic, planning decision-making level have a greater potential impact than optimising the logistics processes derived from them in practice.

Costs and benefits of green logistics

The balance of green logistics measures is mixed: Green logistics measures reduce CO2 emissions, but often lead to higher costs in production and logistics, e.g. when value-added activities are relocated to high-wage countries and some road transport is shifted to rail. However, some green logistics measures to reduce emissions also result in cost savings, thus meeting both environmental and economic requirements. Examples of logistics measures include Reducing delivery days in retail and extending delivery windows in distribution.

ORGAPLAN Logistik GmbH as logistics planning supports your company in the evaluation of planned measures.